Zip Line Construction

Home Zipline Construction

After completing the design and purchasing of gear, you are ready to begin constructing the zip line.

Prepare for zip line construction...clear bushes and plant growth. To establish the clearance area needed along the course use a nylon cord. A parachute cord, kite string or any suitable strong nylon cord will work fine. Run the line from anchor to anchor. Clear area on all sides of the line by several feet.

Unroll the zip line cable from the start to end point. Do not pull the line off the roll from the side creating a "slinky" appearance. The line should unroll by turning the coil. If it is pulled off the coil it will add a full twist to the line for each coil that is taken off. A good way to remove twists is to use an eye/jaw swivel which is connected inline with the turnbuckle. This will allow the cable or any other parts to untwist if necessary. At the start end connect the cable using one of the zip line anchor methods. Do not construct the finish side until after you install the zip line brake since the brake needs to be installed over the cable.

Pull the Cable. Do some preliminary work before pulling the cable tight. Run a nylon cord like a parachute cord from anchor to anchor and establish the height of the cable using this method, as discussed in design a zip line. The amount of sag will be determined by the tension on the cable. The purpose of the nylon line is to visualize how the cable will hang in three dimensions. This will give you an idea how high to initially install the cable. With the help of a buddy and while wearing gloves, tighten the zip line as much as possible by hand. Get the cable pretty close to the height required and connect a cable puller. Use the cable puller to tighten the cable the rest of the way.

Connect the finish anchor. Check the connections on the cable clamps frequently. Look for fraying, over compression, slippage or anything that is out of ordinary. Zip line safety should be taken seriously.

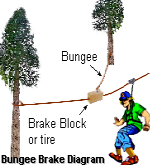

Connect the bungee to the tire or brake block or other zip line brake system you have devised. Make sure the bungee line will be clear of the rider when it engages. This can be done by running it to a tree or mounting in the ground well to the side of the direction of the zip line.

Connect the bungee to the tire or brake block or other zip line brake system you have devised. Make sure the bungee line will be clear of the rider when it engages. This can be done by running it to a tree or mounting in the ground well to the side of the direction of the zip line.

Before sending a person on the zip line, test it numerous times, each time with increasing weight. Do not test with a person. Using carabiners, connect one end of the lanyard to the Trolley and the other to a basket or sling or harness...or anything that can hold rocks. The first tests should be done over a shorter portion of the cable and not the full length. Watch carefully as the Trolley moves. Observe the force with which it hits the brake and decide if it is too fast or too slow. Look for clearance on all sides as it moves down the course, and inspect the anchors. Test repeatedly increasing the weight and distance.

Zip Line Platform.

Oftentimes the height of one of the anchors requires assistance to reach. A platform may be helpful to get on or off the zip line. It's best to build any necessary platforms after the zip line has been set up and tested. The reason is that during testing you may decide the cable height or tension needs to be adjusted. This will affect the elevation the riders enter the landing zone, and therefore the height required for the platform.

Oftentimes the height of one of the anchors requires assistance to reach. A platform may be helpful to get on or off the zip line. It's best to build any necessary platforms after the zip line has been set up and tested. The reason is that during testing you may decide the cable height or tension needs to be adjusted. This will affect the elevation the riders enter the landing zone, and therefore the height required for the platform.

Build the platform as a separate structure from the anchor. Use pressure treated lumber so it will withstand a few seasons of weather. The vertical support posts should be at least 4"x4" in size. For long spans make sure you have large enough joists. The size of the header will determine how far it can span without vertical supports. Additional site-specific factors should be considered, like the anchor, reinforcement of joints, strength of wood, slope, type of soil, etc. The platform deck as a standalone structure only needs to elevate the rider to either get on or off the zip line.

However if the platform needs to be used to hold the zip line cable tension, an engineer needs to be consulted. There are several zip line and challenge course construction companies serving the zip line and ropes industry.

Zip Line Cable Specifications

The zip line cable diameter and specs are very important. Cables receive tension from the dead load. This is called tensile strength. It is simply the tension on the cable caused by the weight and tightness of the cable. There are also loads and stresses on the cable called live loads. Theses are produced dynamically by the rider, the momentum of the rider's movement, winds, and bouncing effect. The cable used for a zip line should be large enough to handle the highest stress from a combination of all loads. Loads increase as the length of the rope increases.

The cable sizes for zip lines depend on the length of the line, the weight of riders and speed. You should check the manufacturer's guidance. Each manufacturer will have slightly different cable strength specifications. There are many different strength grades of cable, so it is important to check the manufacturer's specifications.

Cables are designated as having a breaking strength and working load. The breaking strength is the maximum steady force that the cable will hold before breaking. The Breaking strength is multiplied by a manufacturer's safety factor to determine the working load.

7/19 Steel Cable 1/4" dia. Cable is sold in coiled spools. Typically the length is 250 or 500 feet on the spool. Cables are composed of multiple strands of wire spun in a helix around a core. Manufacturers of the cable (usually called wire rope in industry) list the number of wires per strand with the number of strands per rope. The strands are twisted together and each strand is also composed of wires.

7/19 Steel Cable 1/4" dia. Cable is sold in coiled spools. Typically the length is 250 or 500 feet on the spool. Cables are composed of multiple strands of wire spun in a helix around a core. Manufacturers of the cable (usually called wire rope in industry) list the number of wires per strand with the number of strands per rope. The strands are twisted together and each strand is also composed of wires.

Steel Cable Designation. The type of cable commonly used for zip lines is called "Aircraft cable". It is a special type of cable construction. It is designated aircraft cable because it was originally made for that purpose. However today there are many other uses for this type of cable. Aircraft cable is a more flexible type of cable so it works well for zip lines. This cable is designated by the number of wires per strand, then the strands per cable. For example, the 7x19 designation has 7 strands per cable and 19 wires per strand. This number does not include the core.

It is not essential to use aircraft cable for a zip line. The key is getting your zip line cable to the right diameter for your Trolley, and achieving the minimum working load limit. Don't get a coated cable. I've never used this type but I've heard reports the coating makes the cable slow, and possibly shreds and gums up the pulley.

Zip Line Anchor

Trees used for zip line anchors must be large enough to support the full weight and stress of the cable and riders. This means supporting both the live and dead loads. When looking for a tree to support the anchor, find one in good health, which is a strong species, with stable soil and root system.

Do not use dead trees or trees that show any sign of unhealthy conditions or erosion around the base. It may be necessary to reinforce and add support to existing trees. An arborist can provide an assessment of the health and suitability of the tree. After selecting an appropriate tree, take additional care to protect the root system during construction, and from erosion and compaction. Erosion and compaction will be quickened by the increased foot traffic around the anchor area. A good way to reduce the impact of the additional foot traffic is with the use of a platform. Take as much care as possible to minimize damage to the tree while installing the zip line anchor system and working around the base of the tree. For either chain or eye bolt, be sure to install a backup lanyard which runs completely independent of the anchor. The lanyard can run through the thimble or connect some other place.

Type of Zip Line Anchor. Ensure the anchor is capable of supporting the live and dead loads exerted on it by the cable. Some possibilities for anchoring are:

- Chain around a tree

- Eyebolt through a tree

- Anchored to rock or terrain features

- Connected to platform or an existing structure

Install the Zip Line Anchor to a Tree: Assembling the parts for the zip line and anchor and associated hardware is straight forward. Assemble the starting anchor first. The ending anchor should be the last item installed in order to allow the brake to be set up with the cable running through it.

Using a Chain.

Using a Chain.

- 1/2" chain with rug strip to protect the tree

- 1/2 x 2" bolt to connect the chain

- 1/2" nut

- Flat washer and locking washer

- Turnbuckle

- Thimble

- 3 cable clamps

- cable

- backup system is not shown in picture

Using an Eyebolt.

Using an Eyebolt.

- 15" x 1/2" eyebolt and nuts with locking washers

- 1/4" metal plate backing

- 1/2" nut

- Flat washer and locking washer

- Turnbuckle

- Thimble

- 3 cable clamps

- cable

- backup system is not shown in picture

Assemble the Starting Anchor:

Secure the chain (1) or eyebolt around the tree or structure and through the turnbuckle (2). Slip the thimble (3) through the other end of the turnbuckle and run the cable around the thimble. Pull 20" to 30" of cable through the thimble to allow enough slack to clamp (5). Attach three cable clamps (4) with the bolt side of the clamp on the long end of the cable and the "U" side on the cut end.

Secure the chain (1) or eyebolt around the tree or structure and through the turnbuckle (2). Slip the thimble (3) through the other end of the turnbuckle and run the cable around the thimble. Pull 20" to 30" of cable through the thimble to allow enough slack to clamp (5). Attach three cable clamps (4) with the bolt side of the clamp on the long end of the cable and the "U" side on the cut end.

The ending anchor should be the last item installed. This is necessary so the zip line brake can be assembled by using the free end of the cable. Slip the cable into the tire or brake block and assemble the brake. Leave the ending anchor unsecured until everything else is completed. Use the ending anchor side of the cable to attach and and tighten the cable by using a cable puller. Assemble the ending anchor in the same way the starting anchor was assembled.

There are alternatives to using trees for anchors. Rocks, buildings, play equipment and many other secure objects can be used. All these options depend on the situation. The builder should determine the location and type of anchor using his judgment based on the conditions at the site.

Backup Anchor. Ensure a backup system of lanyards is attached to the anchor. If any part of the zip line anchor fails the backup needs to be able to catch and prevent a fall. The backup lanyards wrap completely around a separate tree or other backup anchoring object and connect to the cable independently of the primary anchor system.

If you mount anchors on poles they need to be buried and anchored with concrete. The depth and size of the poles depend on the tension on the cable. Consult an expert who is able to come to your location and give you site specific assessment. Another method is to set up an "A-frame" support with a ground cable anchoring to some stable object. This gives you a little more flexibility in adjusting the height and location of the launch or landing location.

Zip lines exert a great deal of force on the anchors. The structure that supports the zip line must be able to carry both the dead loads (the weight of the cable) and live loads (the riders and the forces created by momentum, bouncing, wind, etc). The anchor system must be able of supporting the maximum combined loads. If you are using an existing structure as an anchor, ensure it can support the total live and dead loads. Get advice from experts and industry specialists.

Zip Line Brake -- installing a zipline brake

Common methods of creating a brake for a zip line are the tire and wood block methods.

Tire Brake Method. To make a tire brake, get a tire, drill a small hole about 1/4" in diameter on opposite sides. Work the cable through the openings and pull the tire onto the cable. Connect a bungee cord to the tire and secure the other end to a separate anchor far enough down the cable so it will engage with the Trolley and bring the rider to a smooth stop.

Tire Brake Method. To make a tire brake, get a tire, drill a small hole about 1/4" in diameter on opposite sides. Work the cable through the openings and pull the tire onto the cable. Connect a bungee cord to the tire and secure the other end to a separate anchor far enough down the cable so it will engage with the Trolley and bring the rider to a smooth stop.

Brake Block Method. To make a brake block, begin by finding a 6"x6"x12" hardwood block. Drill four bolt holes through the block. Next, cut the block lengthwise. Most circular saws will not cut deep enough to make the 6" cut so it may be necessary to turn it over to finish the cut from the other side. If you have a band saw this would work fine. Next cut a groove about 1/2" in width by 1/4" in depth. This can be done with a circular saw by setting the depth of the blade and making multiple passes--or cut each side of the groove and chisel out the wood with a screwdriver or chisel. Using four carriage bolts, clamp the two pieces of block around the cable. Finally, drill a pilot hole and mount an eye lag screw to the end of the brake block on the zip line side (vs the anchor side). Cut a piece of carpet and tack it to the leading edge of the brake. The purpose of the carpet is to protect the block of wood from the force of the Trolley striking it. In the same manner as described above, connect the bungee to the brake block to a separate tree.

Brake Block Method. To make a brake block, begin by finding a 6"x6"x12" hardwood block. Drill four bolt holes through the block. Next, cut the block lengthwise. Most circular saws will not cut deep enough to make the 6" cut so it may be necessary to turn it over to finish the cut from the other side. If you have a band saw this would work fine. Next cut a groove about 1/2" in width by 1/4" in depth. This can be done with a circular saw by setting the depth of the blade and making multiple passes--or cut each side of the groove and chisel out the wood with a screwdriver or chisel. Using four carriage bolts, clamp the two pieces of block around the cable. Finally, drill a pilot hole and mount an eye lag screw to the end of the brake block on the zip line side (vs the anchor side). Cut a piece of carpet and tack it to the leading edge of the brake. The purpose of the carpet is to protect the block of wood from the force of the Trolley striking it. In the same manner as described above, connect the bungee to the brake block to a separate tree.

CMI Brake Block. This is ready-made and engineered for braking zip lines. It has ball bearing rollers on an internal mount to the cable made of stainless steel, and can handle 1/4" to 1/2" cable size. It has a strong 14,000 pound breaking strength. The zip line brake installs easily and is made especially for use with home zip line kits.

CMI Brake Block. This is ready-made and engineered for braking zip lines. It has ball bearing rollers on an internal mount to the cable made of stainless steel, and can handle 1/4" to 1/2" cable size. It has a strong 14,000 pound breaking strength. The zip line brake installs easily and is made especially for use with home zip line kits.

Belay Glove. A glove designed to withstand friction is an alternative to installing a zip line brake. This may be an option if the speed of the rider is low by the end of the run. This can be incorporated into your zip line design by adjusting the tension of the cable. A good glove used as a brake should fit snugly and have a strap at the wrist area so it won't pull off. Leather seems to provide good dexterity and withstand abrasion.

Belay Glove. A glove designed to withstand friction is an alternative to installing a zip line brake. This may be an option if the speed of the rider is low by the end of the run. This can be incorporated into your zip line design by adjusting the tension of the cable. A good glove used as a brake should fit snugly and have a strap at the wrist area so it won't pull off. Leather seems to provide good dexterity and withstand abrasion.

Climbing Net. Some people have installed a net to catch the rider. The supporting cords for the net should be out of the path of the person riding. The top cord should engage the line hanging down from the Trolley and the person's body is stopped comfortably by the net. The net option for braking also provides the rider a way to dismount simply by climbing down the net when finished.

Climbing Net. Some people have installed a net to catch the rider. The supporting cords for the net should be out of the path of the person riding. The top cord should engage the line hanging down from the Trolley and the person's body is stopped comfortably by the net. The net option for braking also provides the rider a way to dismount simply by climbing down the net when finished.